Energy Effective Customized 20 Ft. Container Workshop

To design and construct a 20ft unit using ISO standard shipping containers according to the following criteria:-

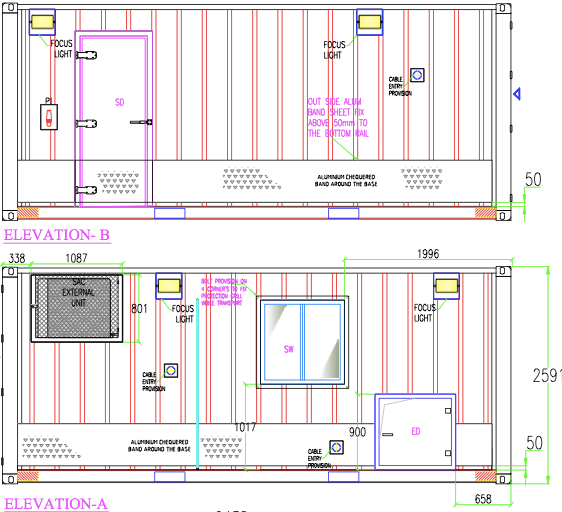

*Shipping containers of sizes 20ft x 8ft x 8.5ft (L x W x H) to be used.

*All the containers will be inspected prior to commencement of work of conversion to ensure it is free from all major defects and that all the containers meet ISO limits and conversion for safe Containers (CSC).

*Regarding complete and fully transportable containers, a CSC Certificate will be issued for transportation of the containers.

*Proper ventilation and lighting (including natural and artificial).

*All units to have thermal insulation to withstand the region’s climatic conditions.

* Durable and long lasting.

* Inlet provision for electrical power supply.

* Water inlet and outlet provisions.

* Fire and safety measures compliant.

* No use of materials harmful to the environment or public health (asbestos etc).

* All units to be fully wired with an external electrical power supply inlet provision.

* To ensure clean cuts, plasma machines are to be used.

* All designs and drawings to be submitted to the engineer before commencing the work.

* A gasket to be fitted to doors to prevent dust and water intrusion.

* All units to be provided with fire extinguishers and smoke detectors.

1. Insulation:

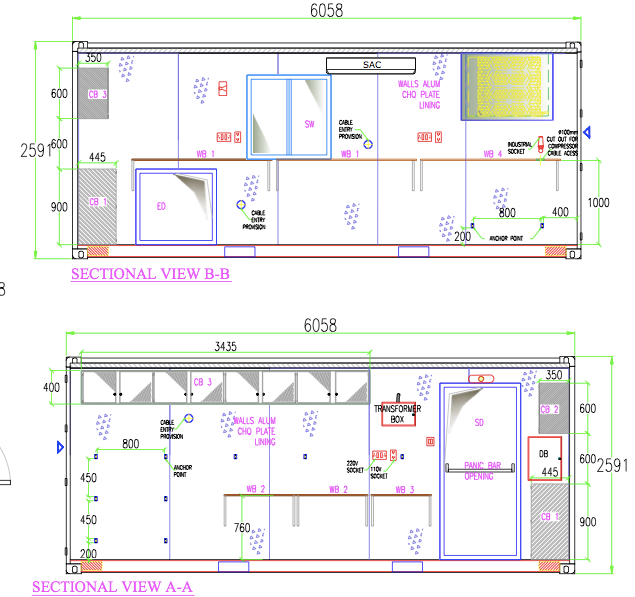

* 50mm Rock wool cool ( heat resistance) insulation and interior side and roof to be lined with 12mm Gypsum board fixed on stud and track hardly with self taping screw and lined with Aluminum chequred plate on Walls and 1mm SS Sheet on the roof.

2. Electrical:

* 2 x Double Fluorescent Light (4’)

* 1 x Single Switch Light

* 2 x Single Switch Socket

* 1 x A/C Switch socket

* 1 x Exit light (Battery backed)

* 1 x Smoke Detector

* 1 x Split A/C Provision

* 1 x Distribution Box

* 1 x Power inlet – 32Amp-Three phase

* 1x440v, 220v, 110v 60Hzpower access industrial socket

3. Floor:

* 9mm Plywood fixed on existing 28mm marine plywood flooring and painting RAL7035 (Grey) Flooring.

4. Workbench

* Working tables with neoprene top, lined with 2mm Aluminum sheet.

* 7 x Work Table foldable with Aluminum top.

5 Painting:

* External concealed marine paint

* Paint RAL – 5013 (Blue) Exterior

* Paint RAL – 1021 (Yellow) Logo

* Paint RAL – 7035 (Grey) Flooring

6 Air conditioning:

* 1 x Split AC Provision with O general Split AC.

7 Windows

* 3 x Aluminum Sliding window with insect screen (3’ x 3’) for natural lighting.

8 Doors:

* 1 x Steel door fabricated on container door for regular use (3’x7’)

* 1 x Escape hatch door - 3’x3’

* Container doors operational

9 Cabinets:

* 3 x Aluminum cabinet with doors

10 Others:

* 2mm Aluminum Chequered plate sheet band around the base.

* Chequered sheet band around the base.

* A Small gap required below exterior chequered plate while fixing to allow sand/water to drawing out without clogging.

* 3 x 3” Pipe holes are required with covering / cap.

* Hooks required securing 6 Cylinder breathing air cascade racks.

* All interior exposed metal items will be painted BLUE-RAL5013.

* Step down Transformer.

* Ladder recessed.

* Smoke detector & Fire Extinguisher.

* Work Tables - 200Kg capacity.

* Chequered plate needs to be fixed in the Exterior steel door also.